| Material | Stainless Steel 316Ti (1.4571) or Hastelloy C-22 (2.4602) |

|---|---|

| Temperature max. | 300° C |

| Pressure max. | 200 bar |

| Reactor vessel Volume | approx. 630 ml |

| Reactor vessel Inner Diameter | 68 mm |

| Reactor Vessel Inner Height | 175 mm |

| Reactor Vessel weight | approx. 6 kg |

| Volume | approx. 500 ml |

| Inner diameter | 62.5 mm |

| Inner height | 165 mm |

| Standard armatures | Rupture Disc, Dip Tube, Valve |

| Pressure Measurement | analog and/or digital |

| Ports (total) | 6 |

| Type of connection | 8 mm Tube Connection |

| Heating Systems (optional) | Electrical (Heating Jacket) |

| Stirring | RV-100 (Magnetic Drive) |

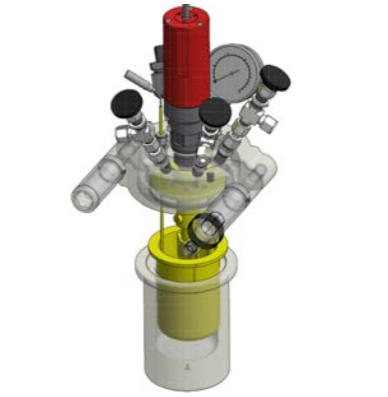

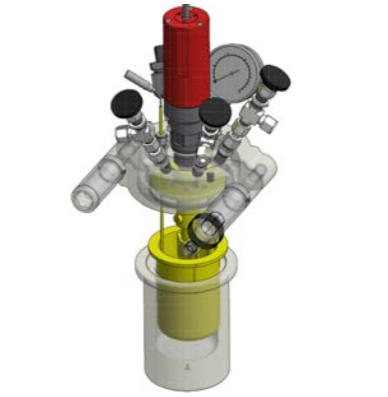

Berghof High Pressure Reactor (BR-500)

Suitable for complex experiments: the high-pressure reactors BR-300, BR-500 and BR-700. A wide range of accessories forms the basis for customer specific configurations. All three basic reactor vessels can be used with or without PTFE inserts. Therefore, these high pressure reactors can be used for volumes up to 980 ml.

As all Berghof high-pressure reactors, the reactors of the BR-300, BR-500 and BR-700 series are available in models made of stainless steel or hastelloy. Due to the innovative construction of the reactor vessels, they can be used both with and without PTFE inserts. Hence, acquisition costs can be reduced tremendously.

Thanks to the large variety of extensions, the BR-300, BR-500 and BR-700 reactors are ideal for complex procedures. The following accessories form the basis for individual configurations:

- Different optional heating concepts (electrical or via fluid)

- Optional stirring via hot plate or magnetic drive

- Various agitator geometrics

- Cooling via double jacket

The different accessories are combined by standard components, such as rupture disc, valve, dip tube and a tool for a safe opening and closing of the reactors. Furthermore, useful supplies like sample holders are available. All reactors of these series have six ports (8 mm tube connection), of which two are free for individual use. The use of t-connections helps to increase the number of free ports.

Usually, these high-pressure reactors are used for synthesis and catalyst researches. Moreover, the size of the reactor vessels allows the use for material test, e.g. in the automotive sector.